NIRMAL INDUSTRIAL CONTROLS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to NIRMAL INDUSTRIAL CONTROLS P.LTD.

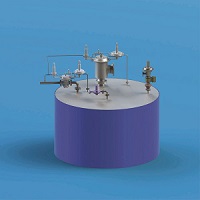

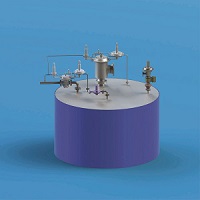

Tank Blanketing Solutions

Why Tank Blanketing?

In refineries & chemicals plants explosive hazards occur if air enters tanks containing volatile flammable liquid during pumping operation. When liquid is removed from a tank or an ambient temperature reduces, vacuum may develop.

Hence, for optimum protection of tank, contents and the environment, a low positive constant gas pressure is maintained in the vapor space of a storage tank. A blanketing gas, nitrogen being the most popular, serves to reduce the oxygen content in the vapor space, making it inert and eliminate the possibility of combustion. It also prevents the ingress of air and moisture from entering the storage vessel. When liquid is removed from tank or an ambient temperature reduces, vacuum may develop. Blanketing system prevents any vacuum from development and maintain the desired blanket pressure. In addition to this, a blanketing gas pressure reduces the evaporation of the stored product to a negligible amount. The result not only conserves product but also greatly reduces emissions. Quality of chemicals which gets affected by contact of moisture or oxygen, is protected by blanketing. These advantages are in addition to the fire protection that is provided.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.